New formwork technology from Big River saves time and money

The construction industry is set to receive significant cost and time-savings as one of Australia’s major formwork material suppliers, Big River Group, introduces Permaform, an extruded PVC permanent wall formwork system.

The construction industry had previously been relying on traditional methods for loadbearing walls such as conventional formed concrete, precast concrete and blockwork systems, which are labour intensive and inflexible. Rech and Zardo, who have over 50 years combined experience in the construction industry, recognised that such timely methods were proving to be unsustainable in todays building climate and so worked on developing a solution.

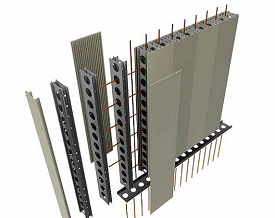

“The construction industry constantly explores opportunities and initiatives to reduce costs and generate efficiencies through modular and efficient construction that not only yield savings in cost and time, but also enhance safety, waste, durability, flexibility and sustainability outcomes,” says Rech. “Permaform addresses these needs and delivers a fast and economical formwork solution in standard wall thicknesses of 110, 150 and 200 mm.”

“Labour costs can represent approximately 60% of the overall cost of blockwork or masonry wall construction depending on project scale, location,accessibility and complexity of work,” says Rech. The system can be installed by anyone experienced in conventional form-working under the supervision of a qualified builder. There are significant savings of costs associated with not using skilled specific tradespeople that are required for traditional block work.

Other cost savings are derived through more refined engineering solutions and the reduction of the required horizontal reinforcing; footing sizes; suspended slab thicknesses; concrete strength and, as less tools and equipment are required, there is a reduced level of safety risk and the associated costs.

Trinity Constructions is currently using Permaform for a medium density residential project in Kellyville, NSW. The four-story, 50 unit dwelling, which features two basements, needed a strong base. “We use Permaform because it is a solid product that isn’t flimsy and doesn’t need bracing,” says Ismail Saleh, Project Manager at Trinity Constructions. “We previously used a similar product that was lighter in weight, but Permaform is more solid and can be put together and concrete filled in one day”.

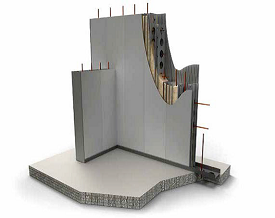

Permaform is made to a standard width of 400 mm but can also be made to measure for particular project specifications. Control joints, which are necessary in conventionally formed concrete walls, are an

unnecessary component with Permaform as it includes internal diaphragms to act as crack initiators, these produce fine cracks at close centres and which are invisible and makes Permaform particularly popular amongst medium to high?density residential builders. Additionally Permaform forms a permanent shell comprising face sheets connected though closely spaced internal diaphrams which are interlocked to resist concrete filling pressures.

Apart from the cost and time savings, as a structural element Permaform has numerous advantages for the builder with paint render or other materials easily applied to achieve decorative and architectural finishes.

Further advantages of Permaform:

• Is a cost effective formwork solution in comparison to traditional formwork methods

• Installation time is reduced due to the lightweight composition, making it more easily manoeuvrable

• The ease of use results in a reduction of safety risks and the associated costs

• It is highly workable and flexible and is not dependant on further tradesmen, tools and equipment such as cranes

• Is performance code compliant (see below)

• Ensures there is minimal onsite wastage as the formwork is ordered to size

• Is impermeable to moisture and has the ability to be a totally waterproof solution system

• Extremely versatile form work system which can be used in residential and commercial projects

• Control joints are not necessary

• Wall thicknesses can be reduced and are available in thicknesses of 110, 150 and 200 mm

Designed and produced for Australian conditions Permaform is compliant with Australian Standards AS3600 Concrete & AS3610 Formwork and satisfies all relevant aspects of the BCA and AS/NZ 3837:1998 fire provisions and acoustic, WH&S and structural integrity.

The system is currently being used in over 10 projects.

Installation and engineering manuals and additional information on the Permaform permanent formwork system from Big River Group are available to download from the Big River Group website at www.bigrivergroup.com.au/product/permaform